These were produced from 1973 till the end in 1977.

Porsche included extra ribs on the casting and thickened other areas slightly, in their effort to improve the design. The only remedy, when this occurs, is to apply sealant on the outside of the block and hope for the best.īlock failure: The latest design of the magnesium block was known as the 7R casting. We certainly share the frustration as it takes so many hours to assemble a motor, only to find out that it starts leaking. USUALLY this is the case, but with the constant expansion and contraction of the motor in operation, we have been seeing some leaks due to Porosity of the blocks.

#Rebuilding a porsche 911 engine free#

And following the correct assembly procedures, one would expect the rebuilt motors to be nice and dry/ free of leaks. Using the finest available sealants, quality seals, and gaskets. Finally, the block gets thoroughly cleaned and sent back to us for inspection and assembly. Afterwards, the individual cylinder holes get machined for roundness and alignment with the crank. There are other holes in the block that get the same treatment with larger steel inserts. these inserts have a larger surface area than the original hole, so allow more grip for the head studs in the “fresh” metal. If not, the machinist does his magic to make it so.Īfterwards the deck on each side, where the cylinder liners sit in the bores, is checked to make sure the bores and deck surfaces are square to the crankshaft center line.Before rectifying this, the head stud mounting holes are drilled, oversized steel inserts are installed. The crankshaft bore is measured to verify that it is straight and correct dimensions.

Next, the block is fastened as if the crankshaft was installed. The block is thoroughly cleaned and inspected for damage and flaws.

#Rebuilding a porsche 911 engine how to#

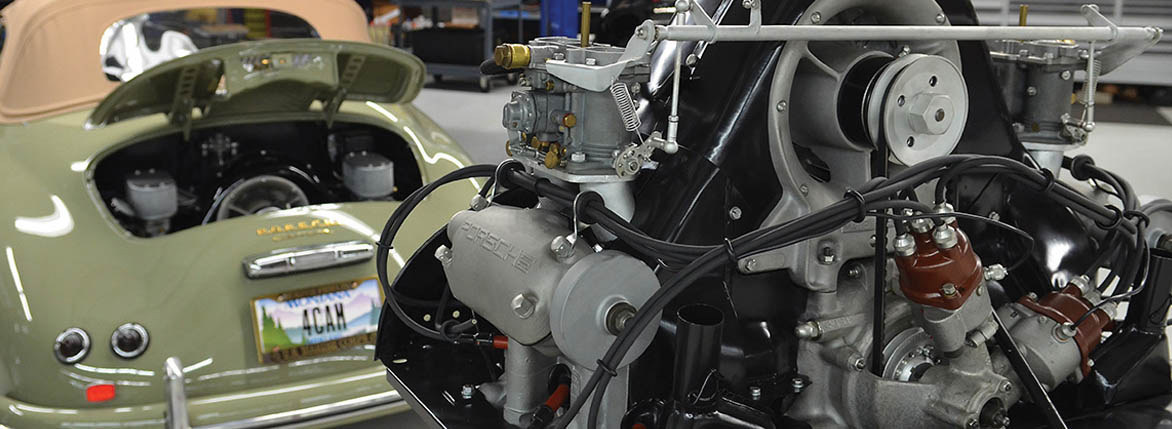

Machine shops to the rescue, or how to properly rebuild a magnesium case engine: When rebuilding the magnesium cased engines, the block is sent to a reputable experienced machinist. Excessive off set wear of the bearings is observed when this happens. Another problem of the magnesium block is the shift in case halves / warpage that can occur. Other studs that are in the block tend to pull from the threaded holes as well. Now we are observing broken head studs from corrosion too. And they changed the type of cylinder head stud, so the alloy matched the expansion rate of the rest of the motor. Porsche did cover some of these under warranty back in the day. The ends of the studs were covered with magnesium that separated from the threaded holes. To start with in the mid 70’s, the higher operating temperatures that the lean burning USA smog legal motors were running yielded massive oil leaks and exhaust leaks from the cylinder head studs pulling loose from the block. With the higher mileage 911’s still on the road, we have been observing the failure of these engine blocks. These last two items are the subject of this essay. Magnesium is an interesting metal: Light in weight, excellent temperature transferring properties, easy to machine, stable…. As an aside, the Factory race department, and others were able to squeeze all the way to 3.0 liters using this block. The initial displacement was 2,0 liters and eventually the design worked up to the 2.7 liter. The first production cars were offered to the public then and with this architecture / design it continued through 1977.

Starting in 1968, the engineers came up with a different casting technique using magnesium, for the block. These were the best for longevity and in fact Porsche brought the aluminum block back into production with the Carrera RS 3.0, Carrera 3.0, 76-77 930 Turbo, and of course the 911SC through the 3.2 Carrera of 1989. Though heavy, these were very stable and typically lasted the lifetime of the car, and beyond. Starting in 1964 Porsche produced the engine blocks in cast aluminum. Wherever those parts have a sealing surface, is a chance for leaks to occur. Its horizontal architecture layers various parts to build a complete engine. The 911 engine has been around since 1964 and in various modifications of the basic design, was used all the way to the water cooled era.

0 kommentar(er)

0 kommentar(er)